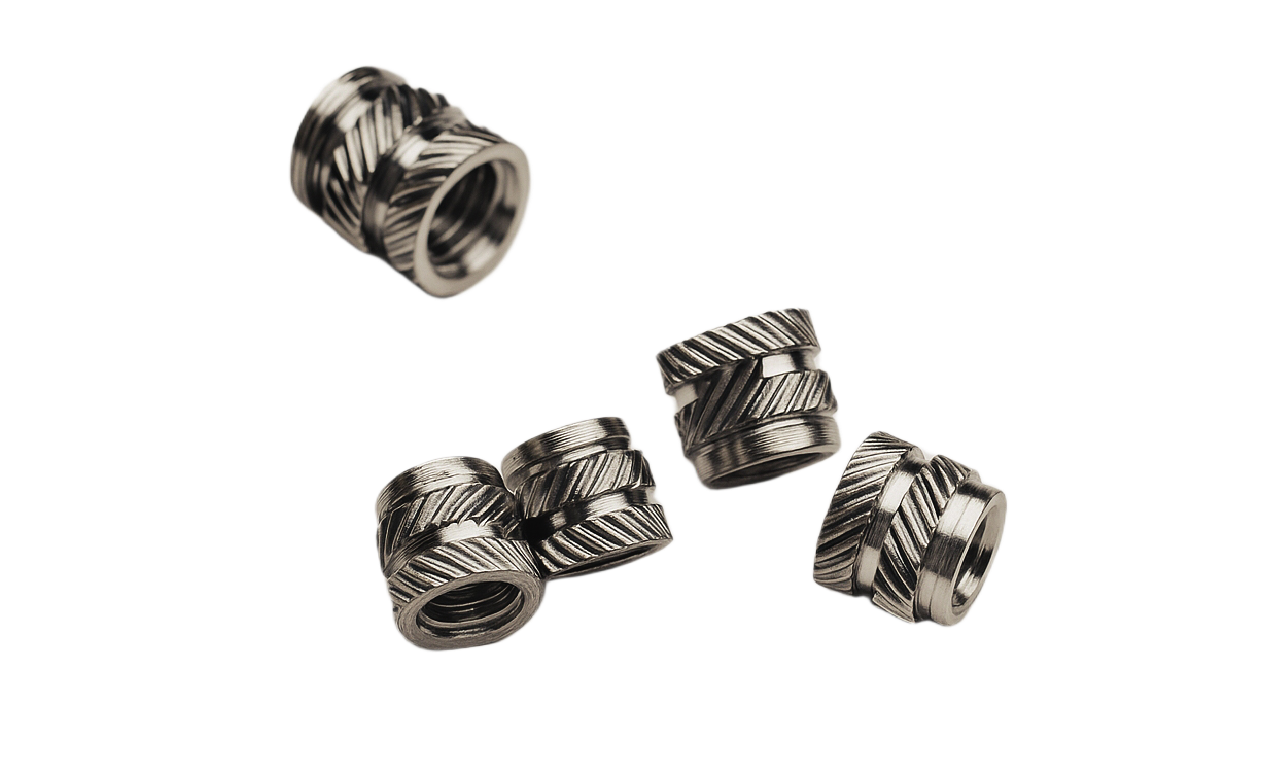

Quality and Precision Engineering

Our AISI 303 inserts are produced using advanced manufacturing techniques and premium-grade stainless steel, ensuring:

-

Exceptional Durability: Resistant to corrosion, wear, and mechanical stress.

-

Precision Engineering: Accurate threading and dimensions for a secure and perfect fit.

-

International Standards Compliance: Manufactured according to ISO and other global quality benchmarks.

-

Consistent Quality: Each insert undergoes rigorous inspection to guarantee flawless performance.

These features make our AISI 303 inserts perfect for critical engineering applications, where reliability and precision are paramount.

Applications Across Industries

Prime Preciturns AISI 303 inserts are widely used in:

-

Automotive & Transportation: Engine components, assemblies, and structural applications.

-

Industrial Machinery: Bearings, gears, and precision equipment.

-

Electronics & Electrical: Mounting and assembly of electronic devices.

-

Construction & Infrastructure: Durable fasteners and mechanical assemblies.

-

Aerospace & Defense: Lightweight, corrosion-resistant inserts for high-precision applications.

Our inserts are engineered to perform reliably under challenging conditions, providing stability, strength, and long service life.

Why Choose Prime Preciturns

-

Manufactured in India: Combining local expertise with global quality standards.

-

High Durability: Built to withstand extreme environments and mechanical stress.

-

Precision Engineering: Accurate threading and dimensions for seamless assembly.

-

Global Export: Trusted internationally for high-quality AISI 303 stainless steel inserts.

-

Custom Solutions Available: Available in various sizes, designs, and specifications to meet industry-specific requirements.